2022-07-05

2022-07-05

The constant temperature and humidity machine is composed of refrigeration system, heating system, control system, humidity system, air supply and circulation system, and sensor system. The above systems belong to electrical and mechanical refrigeration. The working principle and working process of several main systems are described below.

1. Refrigeration system: refrigeration system is one of the key parts of constant temperature and humidity machine. Generally speaking, the refrigeration methods are mechanical refrigeration and auxiliary liquid nitrogen refrigeration. Mechanical refrigeration adopts steam compression refrigeration, which is mainly composed of compressor, condenser, throttling mechanism and evaporator. If the low temperature of our test is to reach -55 ℃, single-stage refrigeration is difficult to meet the requirements, so the refrigeration method of constant temperature and humidity machine generally adopts cascade refrigeration. The refrigeration system of constant temperature and humidity machine is composed of two parts, which are called high temperature part and low temperature part respectively. Each part is a relatively independent refrigeration system. The evaporation of refrigerant in the high-temperature part absorbs the heat of refrigerant from the low-temperature part and vaporizes; The evaporation of low-temperature refrigerant absorbs heat from the cooled object (air in the testing machine) to obtain cooling capacity. The high-temperature part and the low-temperature part are connected by an evaporative condenser, which is both the condenser of the high-temperature part and the condenser of the low-temperature part.

2. Heating system: compared with the refrigeration system, the heating system is relatively simple. It is mainly composed of high-power resistance wires. Because the temperature rise rate required by the test is large, the heating system power is relatively large, and there is also a heater on the bottom plate of the testing machine.

3. Control system: the control system is the core of the comprehensive test chamber, which determines the temperature rise rate, accuracy and other important indicators of the testing machine. Most of the controllers of the testing machine adopt PID control, and a few adopt the control mode of combining PID and fuzzy control. Because the control system basically belongs to the category of software, and this part will not have problems in the process of use.

4. Humidity system: the temperature system is divided into two subsystems: humidification and dehumidification.

Generally, the humidification method is steam humidification, that is, low-pressure steam is directly injected into the test space for humidification. This humidification method has the advantages of humidification ability, fast speed, sensitive humidification control, and is easy to realize forced humidification, especially when cooling.

There are two ways of dehumidification: mechanical refrigeration dehumidification and dry dehumidification. The dehumidification principle of mechanical refrigeration dehumidification is to cool the air below the dew point temperature, so that the water vapor greater than the saturated moisture content condenses and precipitates, thus reducing the humidity. Desiccator dehumidification is to use air pump to extract the air in the test box and inject dry air. At the same time, wet air is sent to recyclable drying for drying. After drying, it is sent to the test box for dehumidification repeatedly. At present, most comprehensive test chambers adopt the former dehumidification method, and the latter dehumidification method, which can make the dew point temperature reach below 0 ℃. It is suitable for occasions with special requirements, but the cost is expensive.

5. Sensor system: the sensors are mainly temperature and humidity sensors. Platinum electric group and thermocouple are widely used in temperature sensors. There are two methods to measure humidity: dry and wet bulb thermometer method and solid-state electronic sensor direct measurement method. Due to the low measurement accuracy of the dry wet ball method, the current constant temperature and humidity box is gradually replacing the dry wet ball with a solid-state sensor to measure humidity.

6. Air supply and circulation system: the air circulation system is generally composed of centrifugal fan and motor driving its operation. It provides air circulation in the testing machine.

Constant temperature and humidity machine (constant temperature and humidity test chamber | programmable constant temperature and humidity test machine | high and low temperature alternating damp heat test chamber) mainly provides constant damp heat, complex high and low temperature alternating test environment and test conditions for the tests of electronic parts, industrial materials and finished products in the research and development, production and inspection links, which is suitable for electronic appliances, communications, chemical industry, hardware, rubber, toys and other industries. The constant temperature and humidity machine system operates through three interconnected systems: refrigerant circulation system, air circulation system and electrical automatic control system; In the refrigerant circulation system, the liquid refrigerant in the evaporator absorbs the heat of the air (the air is cooled and dehumidified) and begins to evaporate. Finally, a certain temperature difference is formed between the refrigerant and the air. The liquid refrigerant also evaporates completely and becomes a low-temperature and low-pressure gaseous state, which is then absorbed and compressed by the compressor (pressure and temperature increase). The gaseous refrigerant absorbs heat through the condenser (air cooling / water cooling) and condenses into liquid. After throttling through the expansion valve (or capillary), the low-temperature and low-pressure refrigerant enters the evaporator to complete the refrigerant circulation process. The temperature range of the constant humidity machine is 0 ℃ ~ 150 ℃, and the humidity range is 30% - 98% RH. According to the test requirements, it can be divided into vertical and desktop.

Alina Essen electromechanical Co., Ltd. was founded in 2003 in Chengdu, Sichuan, the beautiful land of abundance and the hometown of pandas. It is a manufacturing enterprise with independent intellectual property rights. It is a one-stop comprehensive service provider that has long been committed to the R & D, manufacturing, sales and after-sales service of compressed air and post-treatment system and indoor air environment treatment system.

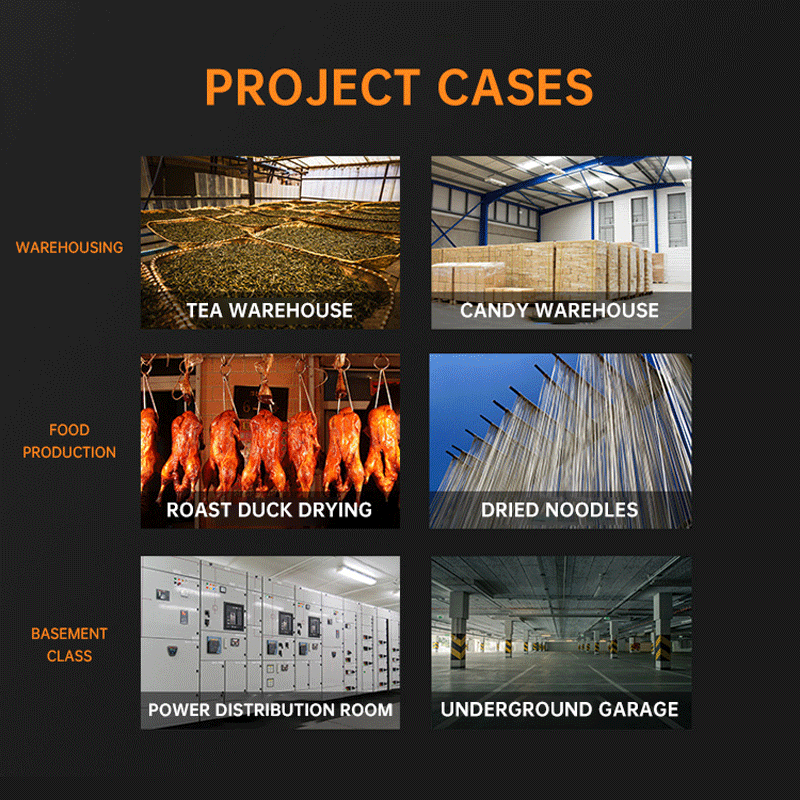

The company has a wide range of products, which can fully meet the production requirements of various industries for compressed air systems and air treatment systems. The main products are: compressed air system (including permanent magnet frequency conversion series, two-stage compression series, low-pressure permanent magnet series, compact series integrating air compressor, air storage tank and cold dryer, special series for laser cutting machine, special series for mine, magnetic levitation centrifugal vacuum series, air suspension centrifugal blower series, etc.); High precision air treatment system: (including industrial dehumidifier series, constant temperature and humidity machine series, industrial humidifier series, air conditioning unit series, etc.).

The products are widely used in: steel, electric power, metallurgy, shipbuilding, textile, electronics, chemical industry, petroleum, mining, light industry, machinery manufacturing, paper printing, food and medical treatment, military science and technology, automotive industry, aerospace, data center, server room, laboratory, museum, precision processing, satellite rocket assembly control room and other industries.

Science and technology create a better future. Alina Essen people have been working hard to provide users with high-quality energy-saving compressed air and efficient, high-precision constant temperature and humidity environment has always been our original intention and mission

Kunhua Li

1419745058@qq.com

Find Us:Alina Essen cross border store